Training

Demand Driven Planner

The environment in which organisations operate is increasingly uncertain and complex. Traditional methods have reached their limit, and information systems are not sufficient to achieve service levels with controlled stock levels. Many organisations are seeing this through their poor stock allocation (oscillating between too much and too little), and the multiplication of files parallel to ERP and APS.

Duration: 2 days

Inter price : 1 300 € excl. tax/person

Intra price : Contact us for more information

Option: certification €250 excl. tax/person

Prerequisites: A few years’ experience in production or planning.

Accessible to people with any kind of disability

Objectives

This course will enable participants to gain a better understanding of flow management within the company and to implement the principles of demand-driven flow.

Evaluations

Validation of knowledge: MCQs

Assessment of satisfaction

Program

MODULE 1: PLANNING IN THE MODERN WORLD

• The MRP (Material Requirements Planning) revolution

• The evidence of a problem

• The “New Normal

MODULE 2: THE IMPORTANCE OF FLOW

• Plossl’s law

• Demonstration of the importance of flow in industry

• Conditions of Plossl’s law

• The whiplash effect

MODULE 3: DISCOVERING A SOLUTION: DECOUPLING THE FLOW

MODULE 4: BECOMING DEMAND-LED

• MRP versus Lean conflict

• What does “demand driven” really mean?

• Demand Driven operational model

• Demand Driven MRP

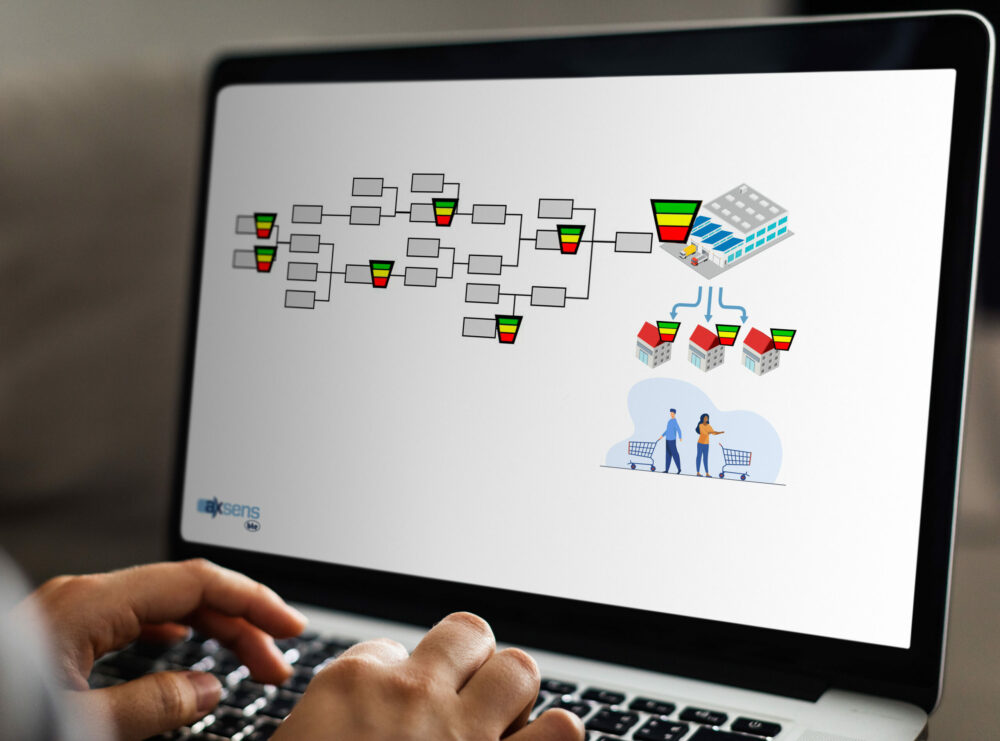

MODULE 5: POSITIONING STRATEGIC STOCKS

• 6 positioning factors

• Decoupled lead time

• Bill of materials matrix

MODULE 6: POSITIONING IN A DISTRIBUTION NETWORK

• Different configurations

• Comparison of push and pull flows

• Positioning throughout the supply chain

MODULE 7: SIZING BUFFERS

• Stocks: Assets or liabilities?

• Buffer profile and buffer zones

• Calculating buffer levels

MODULE 8: DYNAMIC BUFFER ADJUSTMENT

• Calculated, planned and manual adjustments

• Schedule adjustment factor

MODULE 9: DEMAND DRIVEN PLANNING

• Different planning methods

• DDMRP planning process

MODULE 10: COLLABORATIVE AND VISUAL EXECUTION

• Chalenger priority based on scheduled dates

• Buffer status alerts

• Synchronisation alerts

• Collaborative execution

MODULE 11: DDMRP AND THE OPERATING ENVIRONMENT

• DDMRP strategic buffer criteria

• DDMRP / safety stock / reorder point comparison

• DDMRP and WIP management priority

• Comparison between MRP, Lean and DDMRP methods

MODULE 12: DEMAND DRIVEN SALES AND OPERATIONS PLANNING

• Analysis to update parameters and improve the model

• DDS&OP: protecting against critical and strategic impacts

MODULE 13: PROGRAMME SUMMARY

• Summary of the programme and expected benefits of DDMRP

• Getting started with DDMRP

Other Trainings

Training – Black Belt Lean Six Sigma

Training Black Belt Lean Six SigmaThe Lean Six Sigma "Black Belt" leads complex improvement and optimisation projects in services or industry. He or she feeds the company's strategic intelligence and identifies areas for improvement. As a reference, he/she supervises...

Training – Demand Driven Leader (DDL)

Training Demand Driven LeaderThe environment in which organisations operate is increasingly uncertain and complex. Traditional methods have reached their limits and information systems are not sufficient to maintain expected service levels with controlled stock...

Training – Key Characteristics (KC)

Duration : 1,5 daysPrice/Session : 1 495€ excl.tax/person Available : distance, english Accessible to persons with reduced mobilityObjectives Understand the fundamental principles around the key characteristicsUnderstand the subject: From its definition to deployment...