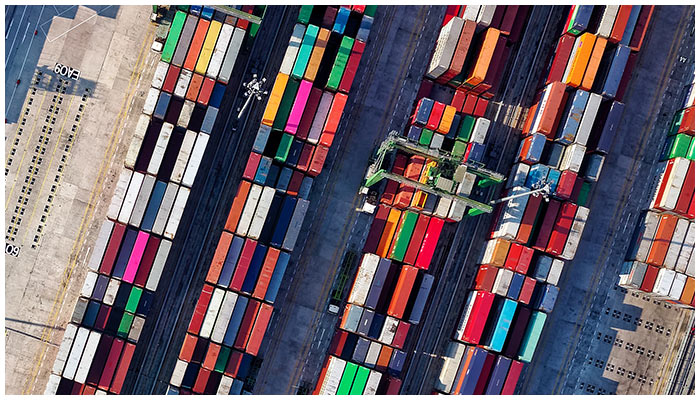

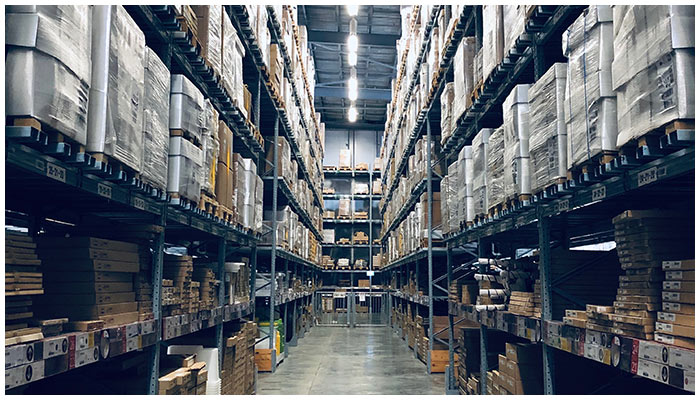

Our mission: Transform your Supply Chain into a growth accelerator

Today, the success of a company is no longer limited solely by the quality of its product or service, but also by its ability to effectively and cost efficiently link supply and demand while adapting to a context of highly volatile and complex markets.

As a key success factor, industrial and distribution companies need to continuously improve their Supply Chain management if they want to remain competitive and stand out from the competition.

An optimized Supply Chain represents an essential competitive advantage insofar as it has a direct impact on the company’s results, particularly with regard to cost reduction, as well as on its balance sheet with the reduction of working capital through inventory optimization.

Faced with the challenges of the Supply Chain to go faster, cheaper while guaranteeing its customers an optimal service, our team supports you, thanks to its expertise in:

- Optimize process integration, which connects your end customer to your suppliers

- Deploy efficient management methods to synchronize physical and information flows

- Select the appropriate digital tools

- Develop employee autonomy

By relying on proven tools and methods, our experts come up with adapted and innovative solutions for your company.

Strategic planning – S&OP (Sales and Operations Planning)

Define the industrial and Supply Chain strategy, the deadlines and inventory policy, anticipate the balancing of resources/needs, make the link between strategy and operations, seek and implement optimization paths.

We offer solutions for Diagnosis and Industrial and Supply Chain Master Plan. Our team relies on its training program and the Serious Game TCC (The Cool Connection) to support business transformation.

Operational planning

The implementation of strategic plans requires planning and managing flows, managing and optimizing stocks, according to the constraints of the field to serve customers.

We support companies to optimize:

- Flow and inventory management

- Optimizing the use of the MRP system in the MRP2 context, calibration of the PDP Master Production Plan

- Implementation of the Pull Flow with Kanban, DD MRP systems

- Planning and scheduling of production activities

Results …

With several successful assignments, Axsens bte provides tools to help you transform your supply chain:

- Simulation of the impact of DD MRP on your inventories and service rates

- Training with our consultants certified by the demand driven institute

- Serious games to discover the concepts in a fun way

- Deployment methodology of DD MRP principles

- Selection of suitable IT systems

Demand-driven flow management: Demand Driven MRP, Adaptive S&OP

In a context of a constantly changing environment, Supply Chain management must continuously adapt to changes and market demand in order to optimise flow management as much as possible while satisfying its customers.

The acceleration of flows and the high variability of the Supply Chain indeed require new methods to react more quickly and efficiently. Planning with MRP or APS type systems, developed in the 1960s, has made great progress but has reached its limits. In today’s complex world, these methods no longer work optimally, especially against « Bullwhip Effects ».

Developed by the Demand Driven Institute in the mid-2000s in the United States, the Demand Driven Material Requirements Planning (DDMRP) method provides an innovative response, adapted to today’s world, by focusing on flow.

Based on Lean management models (pulling flows), 6 sigma (reducing variability), stress theory (protecting bottleneck substations), DD MRP proposes a method whose principles are:

![]() Position stocks at the right (strategic) places in the Supply chain

Position stocks at the right (strategic) places in the Supply chain

![]() Decouple flows to avoid transmitting variability and reduce lead times

Decouple flows to avoid transmitting variability and reduce lead times

![]() Pull flows from real demand

Pull flows from real demand

The logic of the DDMRP is based on setting up intermediate stocks throughout the supply chain to maintain excellent reactivity and agility in the face of change.

This is what we will call buffer stocks (« buffers »), which are introduced at strategic levels in the supply chain and adjusted in real time, according to the volume of demand.

The implementation of the SD MRP principles applies to supply, production, and distribution flows.

DDMRP has already been applied with great success in various sectors such as the automotive, industrial and distribution sectors.

DD MRP, a simple 5-step method

The DD MRP provides tools to analyse the flow, define management parameters and manage the flows that answer 5 questions:

Where to position stocks (stocks, lead times, capacities) to secure the flow?

What level of stocks should be defined (security, operation, batch size, lead time, etc.)?

When to adjust the parameters to take into account market developments, launches, etc.?

How to pull the flow from the real demand of customers?

How to manage the flow with collaborative, visual and dynamic tools?

DD MRP, based on visual management tools

DD MRP methods interface perfectly with all ERP systems.

Simple applications have been developed. Their operation is validated by the Demand Driven Institute. The DD MRP management tools provide clear visibility of situations and allow flow managers to make priority choices.

The DD MRP method applies to both supply management and operational or distribution planning. Companies are getting improvements in inventory levels and service rates.

Managers’ working conditions are improving better communication, better understanding of problems, visibility of room for manoeuvre.

Axsens bte has developed the expertise of Demand Driven MRP since its launch in France in 2013 and is a partner of the Demand Driven Institute.

Our company provides simple tools to simulate the impact of DD MRP on your inventory and service rates. With a proven methodology, our certified DDPP consultants will help you quickly set up a pilot.